PRODUCT

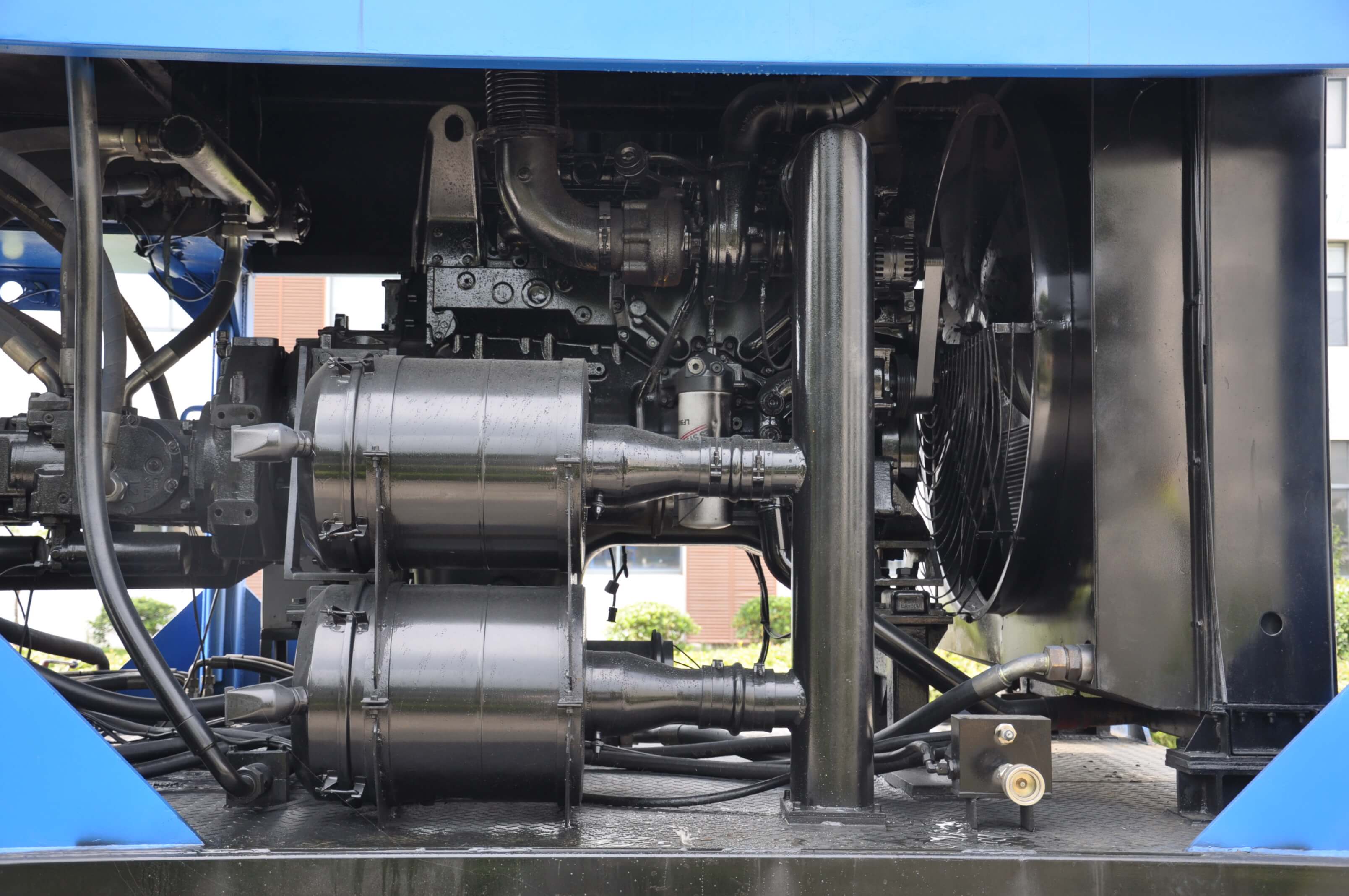

HOME

Goodeng International GD5000-LS

1. Power source: Main power is from 2sets of Chongqing Cummins with each power 368kw/1800rpm. It does not affect continuous running to start single engine according to working condition. If both engines are started the max. torque, max rotation speed, Max. push&pull force and max. push&pull speed can be realized. Rotation and push&pull speed can be feely adjusted by varying the capacity of oil pump and motor. It must be avoided that highest pressure and max. capacity are both running simultaneously, while the two should be reverse proportion. When single engine is running , torsion and rotary speed can be changed by adjusting oil pump or motor capacity. Motor capacity reduced , rotation speeds up and torsion comes down; Oil pump capacity reduced, torsion remains unchanged, rotation speeds up. By shutting off some of the motors or reducing motor capacity push&pull speed could be maintained and push&pull force reduced. Two engines can work alternatively. The idle engine is disengaged by clutch, which not only retrenches fuel, but also extends service life.

2. Main spindle rotation and driving head push&pull adopt close-circuit, effectively reducing oil temperature and abrasion.

3. Coupling between push&pull motor and reducer adopts manual clutch operation. Motors and reducers can be alternatively used, thus with service life prolonged.

4. Floating spindle is aim to unscrew pipes easily, protect thread, eliminate alternating stress and avoide leakage.

5. Floating girder is easy to loading, unloading and transportation, convenient for adjusting entry angle.

6. Unilateral twin cylinder clamp, detachable front and back clamp, clamp being floating in all process.

7. Wire-controlled direction. Wire operation station at back of driving head is roomy and convenient for operation.

8. Driving head rotation and push&pull are proportional linear stepless speed regulation. Working pressure can implement stepless remote pressure control in a range of settings. Torsion and push&pull force can be adjusted any time in operation cab to prevent drill rod from rupture.

9. Configured with slurry pressure discharging device. Display system for mud pressure transmission is safe and reliable which is domestic unique design.

10. Respectively arranged hydraulic oil heating and cooling systems.

11. Remote pressure regulation actualizes proportional variation of push&pull, torque and speed.

12. Independent operation cab with multiple seat, roomy and comfortable, wide view range, warm/cool air condition.

13. Equipped with anti-slip aisle and guardrail at one side and end of girder.

14. Intelligent controlling system, full liquid display , automatic detection, automatic record, automatic analysis, automatic alarming.

15. Drill pipe centralizer in the middle can control speed. The supporting rod height can be adjusted respectively。

16. The host track is detachable to reduce the shipping weight. The wheeled host power station iswalkable and partition, which can independently support host rig walking, placement and support.

Configuration

Engine

Commins

Push & Pull motor

German Rexroth/ Italy Sam

Mud Pump

Lanzhou Shengda/Other

Push & Pull motor

German Rexroth/ Italy Sam

Hydraulic Motor

German Rexroth

Walking Motor

Korea Desung / Miaoyifu / Other

| No. | Item | Theoretical parameter | Remark |

| 1. | Driving head max. theoretical torsion N·m | 150,000 | Differential pressure is 35Mpa,work efficiency not considered. |

| 2. | Driving head max. theoretical push&pull force (KN) | 5,100 | Differential pressure is 35Mpa,work efficiency not considered. |

| 3. | Max. working pressure set in system (MPa) | 36 | Allow temperary max. working pressure 45Mpa |

| 4. | Drill pipe diameter(inch) | From 5-1/2 to 6-5/8 | Petroleum standard drill pipe |

| 5. | Max. length of drill pipe(m) | 9.6 | |

| 6. | Driving head max. rotation speed(rpm) | 85 | |

| 7. | Driving head max. push&pull speed(m/min) | 0-35 | |

| 8. | Main spindle floating distance(mm) | 100 | |

| 9. | Mud pump channel diameter(inch) | 4 | |

| 10. | Max. mud flowing volume(L/min) | 3,000 | |

| 11. | Max. mud pressure (MPa) | 15 | |

| 12. | Entry angle(°) | 8-16 | |

| 13. | Max. clamping force of pipe jaw (KN) | 1,400 | |

| 14. | Max. unscrewing force of pipe jaw(N·m) | 200,000 | |

| 15. | Rig weight(T) | About 46 | |

| 16. | Size(Length×Width×Height (mm) | 17,500×3,100×3,400 | |

| 17. | Power station | About 20T | |

| 18. | Size of crawler-typepower station(mm) | 7,500×2,400×3,200 | |

| 19. | Size of operation room (mm) | 6,000×2,200×2,500 | |

| 20. | Permitted working Temperature ℃ | -20~45 | |

| 21. | Permitted environment humidity % | >90 | |

| 22. | Permitted working altitude(m) | Altitude 0–2,000 | |

| 23. | Referential back-reaming aperture (mm) | φ2,000 | Soil depended |

| 24. | Referential drilling distance (m) | 3,000 | Soil depended |

| 25. | Main pump delivery capacity(ml) | 1,040 | |

| 26. | Main motor delivery capacity(push & pull /rotation)(ml) | 1,300ml/640ml |

| Working condition | Two engine work ,and main pump delivery capacity is 260-520ml/r;Main motor delivery capacity : 160×4=640ml/r |

Two engine work ,and main pump delivery capacity is 260-520ml/r;Main motor Delivery capacity 100×4=400ml/r |

One engine work ,and main pump delivery capacity is 260ml/r;Main motor delivery capacity: 100×4=400ml/r |

| Working pressure (MPa) |

Max.theoretical torque (N·m) |

Max. theoretical torque (N·m) |

Max. theoretical torque (N·m) |

| 10 | 42,741 | 26,713 | 26,713 |

| 15 | 64,112 | 40,070 | 40,070 |

| 20 | 85,482 | 53,426 | 53,426 |

| 25 | 106,853 | 66,783 | 66,783 |

| 30 | 128,224 | 80,140 | 80,140 |

| 35 | 149,594 | 93,496 | 93,496 |

| 40 | 17,096 | 106,852 | 106,852 |

| Working condition | Two engine work , and main pump delivery capacity is 260-520ml/r; Main motor delivery capacity107.5×12 =1290ml/r |

Two engine work , and main pump delivery capacity is 260-520ml/r; Main motor delivery capacity 52.5×8 =420ml/r |

Two engine work , and main pump delivery capacity is 260-520ml/r; Main motor delivery capacity45×8 =360ml/r |

One engine work , and main pump delivery capacity is 260ml/r-520 ml/r; Main motor delivery capacity107.5×12 =1290ml/r |

| Working pressure (MPa) |

Max. theoretical push & pull force (KN) |

Max. theoretical push & pull force (KN) |

Max. theoretical push & pull force (KN) |

Max. theoretical push & pull force (KN) |

| 10 | 1,396 | 454 | 389 | 1,396 |

| 15 | 2,094 | 681 | 584 | 2,094 |

| 20 | 2,792 | 909 | 779 | 2,792 |

| 25 | 3,490 | 1,136 | 974 | 3,490 |

| 30 | 4,189 | 1,363 | 1,169 | 4,189 |

| 35 | 5,026 | 1,636 | 1,402 | 5,026 |

| 40 | 5,584 | 1,817 | 1,557 | 5,584 |